Industry Co-innovation and Solutions

RISE turns operational gaps into scalable enterprise solutions by aligning deep customer process insight with industry benchmarks—driving measurable performance gains and competitive advantage.

Our Cross Industry Solution Approach

RISE provides a comprehensive suite that effectively serves the needs of every key industrial segment and Co-innovation ability establishes the trust necessary to solving issues around complex assets.

Industry Co-innovation

RISE has partnered with leading enterprise industry customers to co-innovate and develop transformational digital worker solutions across multiple domains based on real-life use cases and guidance from Subject Matter Experts to demonstrate the power of SNAP Suite.

- Nuclear Facility Digital Twin – Enhances safety and collaboration with radiation monitoring, real-time data integration, and digital procedures.

- Substation Work Order Digitization – Streamlines field operations with AR-enabled workflows that increase accuracy and safety.

- Unified Substation Monitoring – Combines SCADA and IoT data in a single 3D interface for continuous monitoring.

- Gas Storage Asset Twin – Integrates geospatial, EAM, and IoT data for predictive maintenance.

- Solar Farm Digital Thread – Automates performance management from drone inspection to asset-level overlays.

- XR & VR Learning – Provides immersive training that increases workforce readiness and reduces risk.

- Test Beds – Enable rapid prototyping using realistic data flows, visualization, and simulation.

- Condition Reporting & Job Planning – Data processing and ontology-based insights for optimized job planning.

Co-innovation in action: turning industry expertise into intelligent solutions.

Use Cases

Cross-industry and sector-specific use cases aligned to the SNAP Platform—configurable to your needs and built to deliver exceptional user experiences.

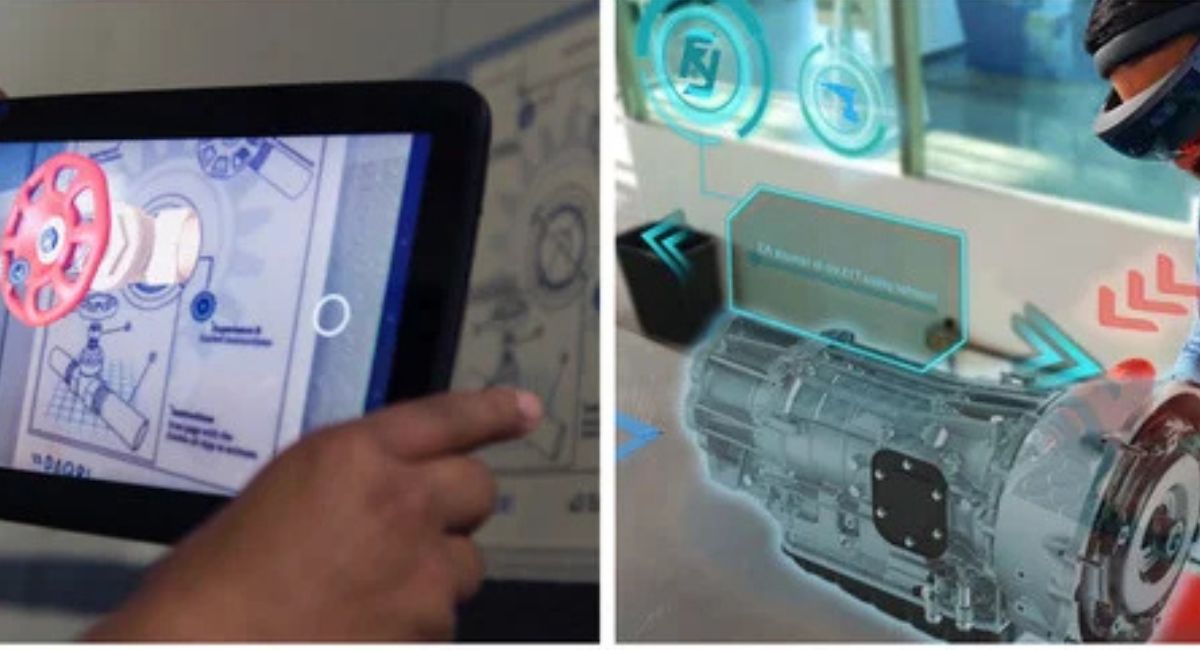

Experiential Learning

A Learner can engage with their virtual instructor and access knowledge beyond

Use Case

Digital operations

Digital operations refer to the strategic use of digital technologies and tools to enhance,

Use Case

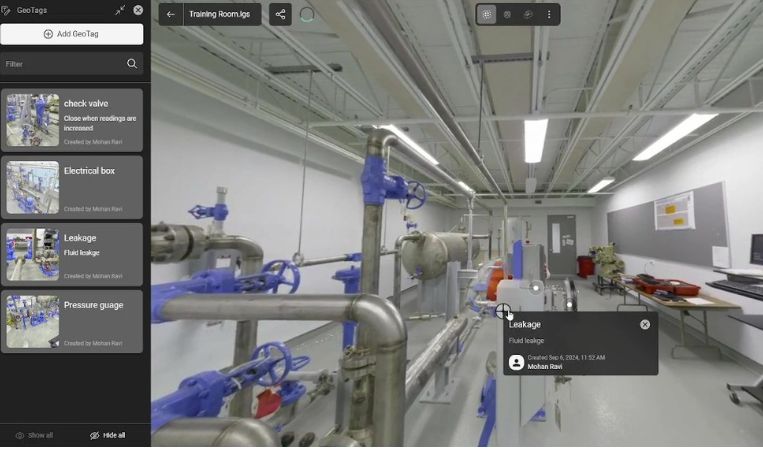

Digital Twin Scenarios

Digital Twin Scenarios achieved through Digital Twin or Virtual Twin as a cross-industry

Use Case

Workforce Safety Training

Utilities recognize safety of the workforce is of utmost significance in its operations and the capability for employees and temporary workers to under go immersive learning….

Use Case

Augmented verification of component

Augmented Verification of Components” likely refers to enhanced methods for verifying the functionality, safety, & reliability of various components within utility systems…

Use Case

Virtual Plant Visits Pre Build

Virtual Plant Visits are immersive, 3D digital walkthroughs of a facility, created using advanced visualization and simulation technology. It allows potential clients….

Use Case

Marine Berth Operations Safety Training

Series of operations involving berth, gangway, deck for an operator are not easy for someone to remember easily by attending the classroom training or reference a document…

Use Case

Inspection Simulation

A gas train simulator is used to train individuals on the safe and efficient operation of gas trains, which are essential components in systems like boilers. Here are some key pieces of equipment you might find in a gas train….Use Case

Complex Equipment Repair Simulations

A large aerospace firm plays a pivotal role in the aircraft program, holding the design and build responsibility for the aircraft’s complete fuselage, including both the forward and aft sections… Use Case

Engine Manufacturing Station

At an engine manufacturing station, we demonstrate the assembly process using advanced automated machines. Below is a breakdown of the steps in the animation that showcases the machine’s operation..

Use Case

Industry Coverage & Support – FAQs :

Find clear answers about how RISE Corp supports critical industries—including utilities, oil & gas, manufacturing, solar farms, substations, and nuclear plants—through digital operations, immersive training, and intelligent workflows.

1. What industries are covered by RISE Corp solutions?

RISE Corp supports a wide range of industries including utilities, oil & gas, manufacturing, solar farms, substations, and nuclear plants, along with other critical infrastructure environments.

2. How does RISE solve common industrial challenges?

RISE addresses key operational challenges like manual process delays, costly & risky training, and complex work instructions using digital twins, immersive experiences, and real-time operational tools.

3. Can RISE solutions be customized for different industries?

Yes. The SNAP Suite and associated services are configurable and tailored to specific industrial needs, helping organizations optimize workflows, reduce risk, and improve safety and productivity.

4. What use cases does RISE address in oil and gas?

RISE supports scenarios like marine berth operations safety training and inspection simulation—helping workers practice complex tasks in a safe, virtual environment that enhances skill and compliance.

5. Can RISE help with safety and compliance in hazardous environments?

Yes. By using immersive training and digital workflows, RISE helps reduce the risks associated with physical training and field operations in high-risk oil and gas environments.

6. What is “Digital Operations” and how does it apply across industries?

Digital operations involve the strategic use of digital tech to streamline business processes, enhance productivity, and reduce costs — applicable in solar form, nuclear plant, utilities, manufacturing, oil & gas, and other sectors.

7. How does RISE support nuclear plant operations?

RISE enables high-fidelity simulations, digital twins, and controlled training environments that support safe operations, maintenance planning, and workforce readiness in nuclear facilities.

8. How does RISE help reduce human error in substation operations?

By digitizing workflows and providing step-by-step visual guidance, RISE ensures consistency in operations and helps teams follow best practices during critical tasks.

9. What are the key benefits of using RISE in high-risk industries?

Organizations benefit from improved safety, reduced training costs, better operational clarity, minimized downtime, and enhanced decision-making through digital operations.

10. How does RISE support end-to-end industrial operations?

RISE supports the full operational lifecycle—from planning and training to inspection, maintenance, and optimization—using digital twins, XR experiences, and intelligent workflows.

Customers and Partners with RISE