Goal and Summary

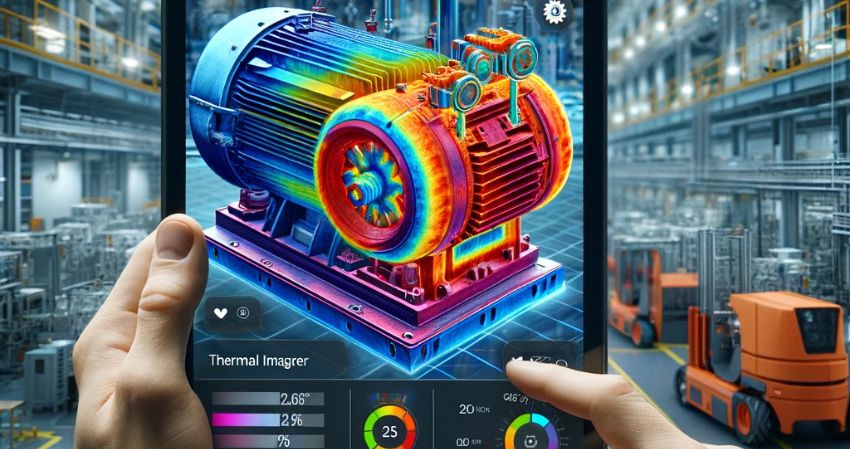

Many substations and facilities may already have special cameras that not only can stream video but also can capture thermal imagery with integration to SCADA systems which have been further enhanced through integration into visualization applications that run on smart devices, wearable devices in addition to traditional computers to enable communication and decision making across operators, supervisors and control rooms augmented with the ability to access intelligent algorithms that can lead to predictive alerts and enhance the collaboration that has never been seen before.

Remote monitoring and collaboration are increasingly essential in today’s interconnected and often geographically dispersed work environments. These technologies enable teams to maintain oversight, ensure operational efficiency, and collaborate effectively, regardless of location. This is particularly crucial in industries like utilities, manufacturing, healthcare, and construction, where real-time data and communication are vital for safety, productivity, and decision-making.

Key Components of Remote Monitoring:

IoT and Sensor Integration:

- Real-Time Data Collection: Sensors and IoT devices placed on equipment, infrastructure, or within environments collect continuous data on variables such as temperature, pressure, vibration, and energy usage.

- Predictive Maintenance: By analyzing sensor data, systems can predict when equipment is likely to fail or need maintenance, allowing for proactive servicing and reducing downtime.

- Environmental Monitoring: Sensors track environmental conditions such as air quality, humidity, and noise levels to ensure compliance with safety standards and optimal working conditions.

Centralized Monitoring Platforms:

- Dashboards: Centralized dashboards provide real-time visualization of data from various sources, allowing operators and managers to monitor operations from a single interface.

- Alerts and Notifications: Automated alerts can be triggered when certain thresholds are breached, enabling quick responses to potential issues.

- Remote Access: Authorized personnel can access monitoring systems from anywhere via secure internet connections, ensuring continuous oversight even when off-site.

Digital Twins:

- Simulation Models: A digital twin is a virtual replica of a physical asset, system, or process. It can be used to simulate different scenarios, predict outcomes, and optimize operations.

- Real-Time Updates: Digital twins are continuously updated with real-time data from the physical counterpart, providing an accurate and current representation of the asset’s status and performance.

AI and Machine Learning:

- Anomaly Detection: AI-driven systems can detect anomalies in real-time data, identifying issues that may not be immediately apparent to human operators.

- Data Analysis: Machine learning algorithms analyze large datasets to uncover patterns, trends, and insights that inform better decision-making and operational efficiency.

Benefits of Remote Monitoring and Collaboration:

- Increased Efficiency: Teams can monitor and manage operations in real-time, reducing the need for on-site presence and enabling quicker responses to issues.

- Cost Savings: Remote monitoring reduces travel costs and downtime by allowing issues to be detected and resolved before they escalate.

- Enhanced Safety: Continuous monitoring of hazardous environments or equipment can prevent accidents and ensure that safety protocols are being followed.

- Global Collaboration: Teams can collaborate across different locations and time zones, bringing together the best talent and expertise from around the world.

- Improved Decision-Making: Access to real-time data and collaborative tools enhances the quality and speed of decision-making, leading to better outcomes.

Applications Across Industries:

- Utilities: Remote monitoring of infrastructure like power grids, pipelines, and water treatment plants helps in maintaining efficiency and safety, while collaboration tools enable teams to coordinate responses to outages or other issues.

- Manufacturing: Factories can be monitored remotely for equipment performance and environmental conditions, while teams collaborate on production schedules, quality control, and maintenance planning.