Augmented Component Verification: Benefits & Impact

Augmented verification of components is a cutting-edge system designed to enhance the safety and efficiency of radiation workers by integrating real-time monitoring, digital twins, and augmented reality (AR) technologies. It ensures that radiation levels and equipment performance are continuously tracked, helping organizations maintain strict safety standards while reducing risks.

This approach not only minimizes human exposure to hazardous environments but also ensures compliance with industry regulations and improves operational performance.

Demo and Features

Augmented verification for radiation safety showcases how real-time monitoring, digital twins, and AR technologies come together to ensure the safety of radiation workers. Below is a walkthrough of a typical demo scenario.

- Real-Time Monitoring Setup.

- AR-Based Inspection and Verification.

- Triggering Alerts and Evacuation.

- Simulation and Emergency Training.

- Post-Training Feedback and Reporting.

- Real-Time Monitoring.

- Digital Twin Technology.

- Augmented Reality (AR) Inspections.

Benefits of Augmented Verification of Components

Helping organizations maintain strict safety standards while reducing risks. This approach not only minimizes human exposure to hazardous environments but also ensures compliance with industry regulations and improves operational performance.

- Minimized Human Exposure.

- Real-Time Safety Assurance.

- Enhanced Equipment Reliability.

- Improved Emergency Preparedness.

- Expensive repairs and reduces downtime.

- Increased Worker Confidence.

Key Components of Augmented Verification System

Digital Twin Integration

- Creates virtual models of radiation-related equipment (e.g., X-ray machines, reactors) that replicate their behavior in real time.

- Continuously monitors performance and radiation levels to detect abnormalities early.

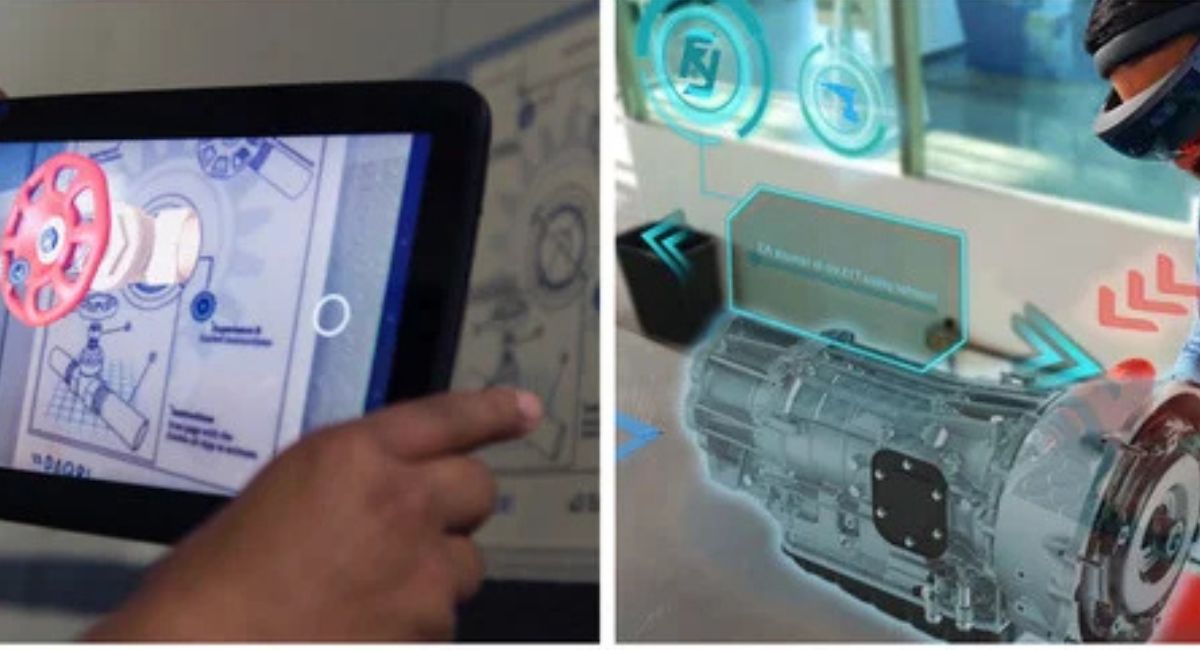

Augmented Reality (AR) Inspections

- Workers use AR headsets or mobile devices to view real-time safety data overlays while inspecting equipment.

- AR highlights critical areas, guiding workers through safe maintenance and operational tasks.

Real-Time Monitoring and Alerts

- Radiation sensors track environmental exposure levels, providing live updates to ensure workers remain within safe limits.

- Automated alerts are triggered when thresholds are exceeded, initiating preventive or corrective actions.

Automated Safety Equipment Verification

- The system checks the functionality and calibration of protective equipment, such as lead aprons and dosimeters, before use.

- Ensures that all safety protocols are followed through automated workflows.

Simulation and Training with Digital Twins

- Simulates emergency scenarios, such as radiation leaks, to improve worker preparedness and emergency response.

- Enables AR-driven training drills to reinforce safety protocols.

Exposure Tracking and Reporting

- Tracks individual exposure levels over time, ensuring compliance with regulatory exposure limits.

- Automated documentation supports audits and safety compliance.

Benefits of Augmented Verification for Radiation Safety

- Minimized Human Exposure: AR and remote monitoring reduce time spent in high-radiation areas.

- Real-Time Safety Assurance: Immediate alerts allow quick corrective actions, ensuring safe operations.

- Enhanced Equipment Reliability: Continuous monitoring ensures equipment operates safely and efficiently.

- Improved Emergency Preparedness: Simulations help workers respond effectively to real-world emergencies.

- Regulatory Compliance: Automated tracking and reporting simplify audits and ensure adherence to safety standards.

- Cost Savings: Early detection of issues prevents expensive repairs and reduces downtime.

- Increased Worker Confidence: Real-time monitoring builds trust and promotes a culture of safety.