Goal and Summary

On a typical shop floor assembly operators, especially, in assemble to order or engineer to order manufacturing scenarios have to review the engineering information, specific work instructions related to the order in process and individual notes in addition to the assembly order activity lists which become a hindrance for inexperienced workforce resulting in defects.

Having the ability to visualize all related information in a single view irrespective of the device reduces work stress and improves accuracy due to real time access to information.

In manufacturing, particularly in complex assembly processes, clear and accurate instructions are critical to ensuring that components are assembled correctly and efficiently. Assembly Order Visualization (AOV) and enhanced instructional tools, often powered by digital and augmented reality (AR) technologies, provide workers with a step-by-step guide to the assembly process. These tools help reduce errors, improve productivity, and ensure consistency across production lines.

Key Components of Assembly Order Visualization and Instructions:

Digital Assembly Instructions:

- Interactive Manuals: Digital assembly instructions are often interactive, allowing workers to navigate through the assembly process step by step. These manuals can include detailed diagrams, videos, and 3D models that show exactly how each component should be assembled.

- Customization: Instructions can be tailored to specific products, variants, or production lines, ensuring that the guidance provided is relevant to the task at hand.

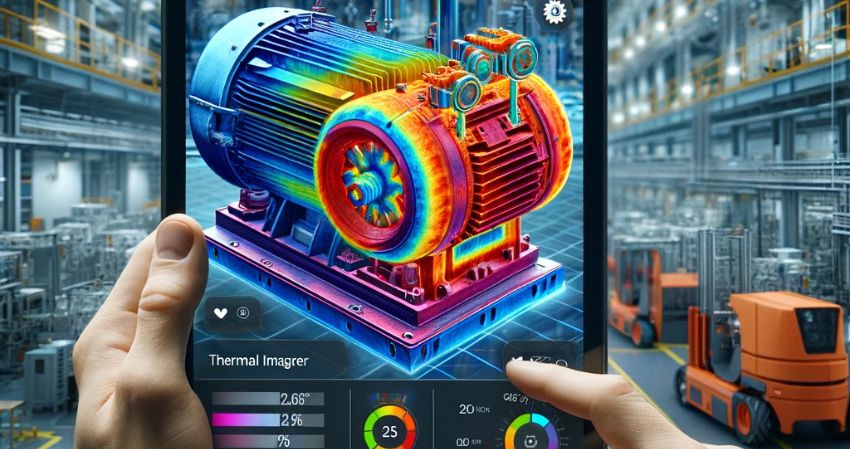

Augmented Reality (AR) Guidance:

- AR Overlays: Using AR devices like smart glasses or tablets, workers can see overlays of digital instructions directly on the physical components they are assembling. This might include highlighting where a part should be placed, indicating the correct orientation, or showing the tools required for the task.

- Real-Time Error Detection: AR systems can detect if a component is being assembled incorrectly in real-time and provide instant feedback, allowing the worker to correct the error before proceeding.

3D Visualization Tools:

- 3D Models: 3D visualization tools allow workers to view detailed models of the product they are assembling. They can rotate, zoom in, and explore the model from different angles, gaining a comprehensive understanding of the assembly process.

- Exploded Views: These views break down the assembly into individual components, showing how each part fits together within the larger product. This is particularly useful for complex assemblies where the relationship between components may not be immediately obvious.

Training and Skill Development:

- Virtual Assembly Simulations: Before working on the actual product, workers can practice assembly tasks in a virtual environment. These simulations provide hands-on experience without the risk of damaging components.

- Ongoing Learning: As new products or processes are introduced, workers can quickly adapt by accessing updated digital or AR-based instructions, ensuring they are always following the latest procedures.

Benefits of Assembly Order Visualization and Instructions:

- Error Reduction: By providing clear, visual instructions, these tools significantly reduce the likelihood of assembly errors, ensuring that components are assembled correctly the first time.

- Increased Efficiency: Workers can complete assembly tasks more quickly and with greater confidence, improving overall productivity on the production line.

- Consistency: Standardized instructions ensure that all workers follow the same process, leading to consistent product quality across different shifts and production lines.

- Enhanced Training: New employees can learn assembly processes faster through interactive and visual tools, reducing the time required for training and increasing their effectiveness on the job.

Conclusion: Assembly Order Visualization and Instructions represent a significant advancement in manufacturing processes, leveraging digital and AR technologies to improve accuracy, efficiency, and consistency. By guiding workers through the assembly process with clear, visual instructions, these tools help ensure that products are assembled correctly and efficiently, ultimately enhancing product quality and reducing costs associated with errors and rework. As manufacturing continues to evolve, the integration of these technologies will become increasingly important in maintaining competitive and agile production environments.